| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : JX

Model Number : CoCrWC 6B

Certification : ISO 9001

Place of Origin : CHINA

MOQ : 1KG

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Delivery Time : 10-20DAYS

Packaging Details : Plywood box with shock absorbing foam board

Cobalt Alloy Stellite 6B Rod Information

The high-purity metal raw materials such as cobalt, chromium, tungsten, nickel and molybdenum are prepared by high-temperature smelting, casting, forming, forging, rolling, heat treatment, turning, drilling, polishing and electroplating, and each process will be completed strict quality inspection.

Cobalt (CO) is about 60% , is the matrix element, giving the alloy excellent high temperature strength, thermal fatigue resistance and impact resistance

Chromium (CR) is about 30% , which can form a dense chromium oxide (CR2O3) passivation film to improve corrosion resistance and oxidation resistance

Tungsten (W) is about 4.5% , and combines with carbon to form hard carbide, which enhances hardness and abrasive wear resistance

Features:

Application:

Cobalt Alloy Stellite 6B Rod Dimension

| Grade | Stellite 6B |

| Diameter | Φ10-200mm |

| Length | 100-2000mm |

| Hardness | 40-44HRC |

| Tensile Strength | ≥930MPa |

| Shape | Round |

| Density | 8.40g/cm³ |

| Standard | AMS,DIN, ASTM, GB |

| Certification | ISO9001 |

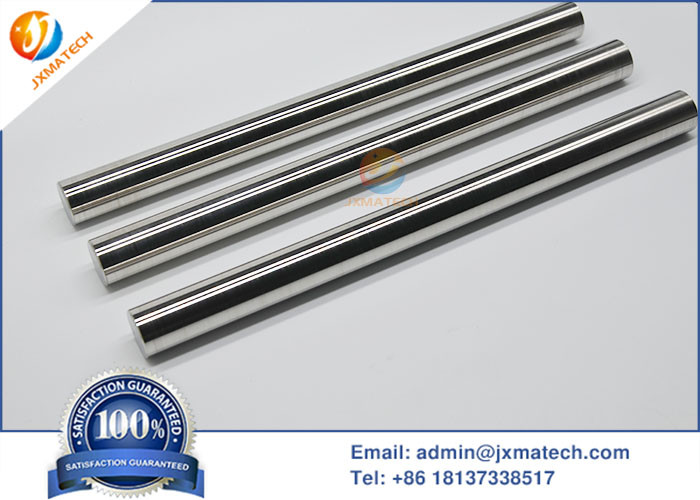

Cobalt Alloy Stellite 6B Rod Pictures

|

|

Cobalt Alloy Stellite 6B Rod Images |